Jéssica Pereira Duarte1, Paulo Henrique Alfenas da Silva2, Paschoal Cataldi3, Débora Chácara4 and Raphael Vieira da Costa5

1. Geotechnical Engineer at Pimenta de Ávila, Belo Horizonte, Brazil

2. Senior Geotechnical Consultant

3. Executive Manager

4. Geotechnical Engineer

Norsk Hydro, Belém, Brazil

5. Head of B&A Technology at Norsk Hydro, Rio de Janeiro, Brazil Corresponding author: paulo.alfenas@hydro.com

Abstract

The need for an adequate understanding of tailings yielding and flow behavior has been the subject of rheological studies in the mining industry. In this context, hydrodynamic tailings studies incorporated advanced models better to represent the rheological phenomena of these materials on movement. Brazil is one of the leading ore processors of bauxite for alumina production and hence, the cradle of large bauxite residue disposal areas. Based on the development of residue disposal methodologies applied explicitly in the alumina industry, the rheological characterization is considered an important stage for a better understanding of residue behavior as a non-Newtonian fluid. This paper evaluates the applicability of rotational tests with a controlled shear rate regarding the rheological characterization of residue on a viscous basis. For this purpose, the paper describes the methodology applied to the beforementioned laboratory tests performed in the bauxite residue dewatered by drum filters. Undisturbed and disturbed samples were collected at different depths within the bauxite residue disposal area and tested over different moisture content conditions. Finally, based on the laboratory test results, the study evaluates the influence of the moisture content of samples on the flow and viscosity curves.

Keywords: Filtered bauxite residue, Rheological characterization.

1. Introduction

The tailing’s yielding and flow understanding has been the subject of research involving the mining and industry sectors. To better understand the bauxite residue behavior and incorporate an advanced dam break model, Hydro Alunorte has investigated the bauxite residue disposal area DRS1. The bauxite residue disposal area of Hydro Alunorte started its operation in 1995 on a 270 hectares site. The refinery generates over 4 200 000 tonnes of bauxite residue annually, deposited in the two bauxite areas, the DRS1 and the recent expansion DRS2. The operations consisted of cyclical disposal, alternating the deposition to allow the residue paste to desiccate under solar incidence. The drum filter disposal methodology required large areas for natural drying and was withdrawn with the implementation of the press filter plant for bauxite residue filtration.

For most mineral residues, such as suspensions, pulps, or residue pastes, the proper understanding of the behavior regarding deformation and flow depends not only on the physical determination of the phenomena of elasticity and plasticity but also on the consideration of their viscous nature.

In this context, Hydro Alunorte performed a broad site investigation, collecting undisturbed and disturbed samples. The material was tested in the laboratory for geotechnical and rheological characterization to enhance the dam break studies developed for the site.

2. Material and Methods

The knowledge of the rheological properties of tailings and residues makes it possible to portray their crucial characteristics in flow and deformation, evaluating the influence of solids content on their flow and viscosity curves and the development of time-dependent phenomena [1].

There are two types of apparatus commonly used to measure the viscosity of materials: viscometers and rheometers. Viscometers are simple devices that measure viscosity as a function of velocity or shear rate controlled during the test. At the same time, rheometers are more sophisticated devices that allow other rheological tests – such as rotational, creep, relaxation, and oscillatory tests.

Within the scope of rheometry, both liquids and solids can be tested. Among the most common test equipment, there are rotational and oscillatory rheometers. Rotational tests are used to characterize the viscous behavior of the material [2]. On the other hand, creep, relaxation and oscillatory tests allow the investigation of the viscoelastic and time-dependent behavior.

The rotational test is used in this research to determine the viscous behavior of material from flow and viscosity curves, in addition to providing the yield stress (τy). The viscosity studied in rotational tests is called dynamic viscosity and is determined according to Equation (1) by the relationship between the shear stress and the shear rate.

The rheological tests were performed in the laboratory LME (Laboratório de Microestrutura e Ecoeficiência de Materiais) of University of São Paulo and used a rotational rheometer with vane geometry to measure the bauxite residue stress-strain relationship. The test was performed in two phases. The first consisted of accelerating the strain rate from 0 to 70 s-1, and the second was decelerating in inverse the strain rate to null. The acceleration cycle is related to the start of motion and static parameters, while the second cycle refers to the material rest and dynamic parameters. This method is known as the shear-flow test.

2.1 Sampling

Thirty samples were collected using push tube sampling at different depths and spatially distributed along 09 investigation isles, shown in Figure 1. The isles’ location covered different moisture conditions, so the entire bauxite residue disposal area was investigated.

The location definition followed the criteria (i) prioritized areas where the drum filter residue had been more recently disposed; (ii) areas potentially mobilized in the dam break studies; (iii) depths with bauxite residue with higher moisture content.

Additionally, 20 l of supernatant effluent from DRS1 was collected and stored in a hermetically sealed recipient.

The topographic coordinates of the collection points were registered in SIRGAS2000 datum.

![Figure 1. DRS1 Bauxite Residue Disposal Area – Sampling Isles [3]](https://www.pimentadeavila.com.br/wp-content/uploads/2024/03/Figure-1.-DRS1-Bauxite-Residue-Disposal-Area-–-Sampling-Isles-3-1024x915.png)

The collection was performed using a thin wall stationary piston sampler with 100 mm diameter and 800 mm length. The disturbed samples were removed from the sampler, stored in doubled plastic bags, hermetically sealed, and packaged in 20 l recipients.

The undisturbed samples were collected carefully to maintain the in-situ characteristics and followed the specified procedures. To transport the samples from the drilling rig to the testing laboratory in São Paulo, the paraffin sealed samples received identification. They were vertically positioned in polystyrene bins filled with foam. The undisturbed samples were extruded from the Shelby tube sampler and placed in the vane cups with as little disturbance as possible.

2.2 Geotechnical Characterization

The characterization campaign included:

- Apparent specific mass, determined by gas helium pycnometer, using Multi-Pycnometer Quantachrome.

- Particle size distribution, determined by laser granulometry with detection range of 0.1- 350 microns, using Helos-Sympatec GmbH.

- Natural moisture content, following the procedures of ABNT NBR 6457:2016 [4].

- Atterberg limits, following the procedures of ABNT NBR 6459:2016, version 2017 [5],and ABNT NBR 7180:2016 [6].

2.3 Rheological Test

The solids content of bauxite residue samples varied from 30 % to 80 % in mass, by adding the effluent collected in DRS1—this procedure aimed to evaluate the rheological behavior of the bauxite residue for different moisture conditions. The test results were plotted in the yield stress and viscosity versus solids content curve.

As for the test performance conditions, three distinct sample groups were considered: i) undisturbed samples; ii) disturbed samples molded to their in situ solid content; iii) disturbed samples molded with different solids contents, varying between 30 % and 73 %.

The groups of disturbed samples considered an initial drying stage when the moisture content was measured using the oven drying method, followed by mixing and homogenizing the residue samples with collected supernatant effluent from DRS1.

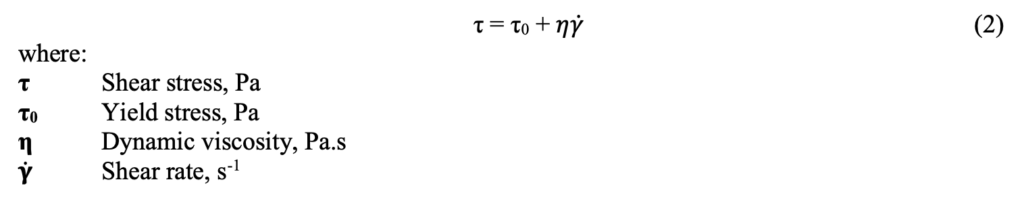

The rheological parameters (yield stress and viscosity) were approached using Bingham’s mathematical model, since the model applies to fluids classified as plastic and pseudoplastic, such as bauxite tailings [7]. The mathematical model consists of regression stress-strain curves, considering the characteristics of the resulting curves as representative of the rheological parameters, according to the relationship presented by Equation (2).

Authors pointed out that mining tailings and soils mostly show a non-Newtonian [8]. Unlike Newtonian fluids, materials with non-Newtonian behavior exhibit rigid-body behavior up to critical shear stress, called yield stress.

Therefore, the yield stress can be understood as the critical shear stress that must be exceeded before the material presents irreversible deformations and starts to flow. After the yield stress is reached, the material is governed by elastic behavior.

In summary, the study considered obtaining the yield stress and dynamic viscosity from the flow and viscosity curves, evaluated by Bingham’s mathematical model, applied to undisturbed and disturbed samples collected from the interior of a bauxite residue deposit. Molded disturbed samples for different solids content conditions evaluated the influence of moisture content in rheological behavior.

The samples were prepared following the steps:

Step 1 – Drying

The wet tamping prepared the samples in three layers with a metal socket dropped 15 times from a height of 2 cm at the natural moisture content. Once the material got loose, it was dried in two different drying methods to evaluate the method’s efficiency. The first method is based on air drying, with manual deagglomeration until it reaches the hygroscopic moisture content. The second method has the samples in an oven at 40 oC for 48 hours until observed mass constancy and deagglomerated. The drying process applied to the tests was the second method.

Step 2 – Moisture adjustment

The samples were blended in the laboratory, and the suspensions were prepared and mixed in different water contents, approximately 73 %, 70 %, 60 %, 50 %, and 30 % in mass, through standard laboratory mixing procedure, controlling the mixing frequency and time to avoid increasing the temperature of the samples.

Performing the tests at different solids content is critical since the residue presents significant variability in the deposit caused by weather and deposition conditions. Nevertheless, the disturbing sample preparation might lead to greater efficiency of deagglomeration if compared to natural conditions.

Step 3 – Rotational Test

The flow test consists of the controlled application of a force or deformation and the measure of the material strength. This method evaluates the rheological profile and is used to quantify the properties such as yield stress and viscosity. Aspects such geometry – concentric cylinder, cone plate, parallel plates, for instance – and material condition might influence the rheological properties.

The rotational tests performed with a coaxial vane-type rheometer consisted of shear-stepped flow, varying from 0 to 70 s-1, with two consecutive shear cycles to ensure the total mass disturbance. The first cycle provided the static yield stress, which can be approached as the peak of the shear stress near zero shear rate. On the other hand, while flowing, after the static yield stress is reached, the rheological Bingham model was applied in the second cycle to estimate the dynamic yield stress.

The bauxite residue thixotropy is observed by the viscosity reduction with the shear rate increasing and can be estimated by taking the difference between the acceleration and deceleration curves.

The tests were performed in duplicate for each sample.

3. Results and Discussions

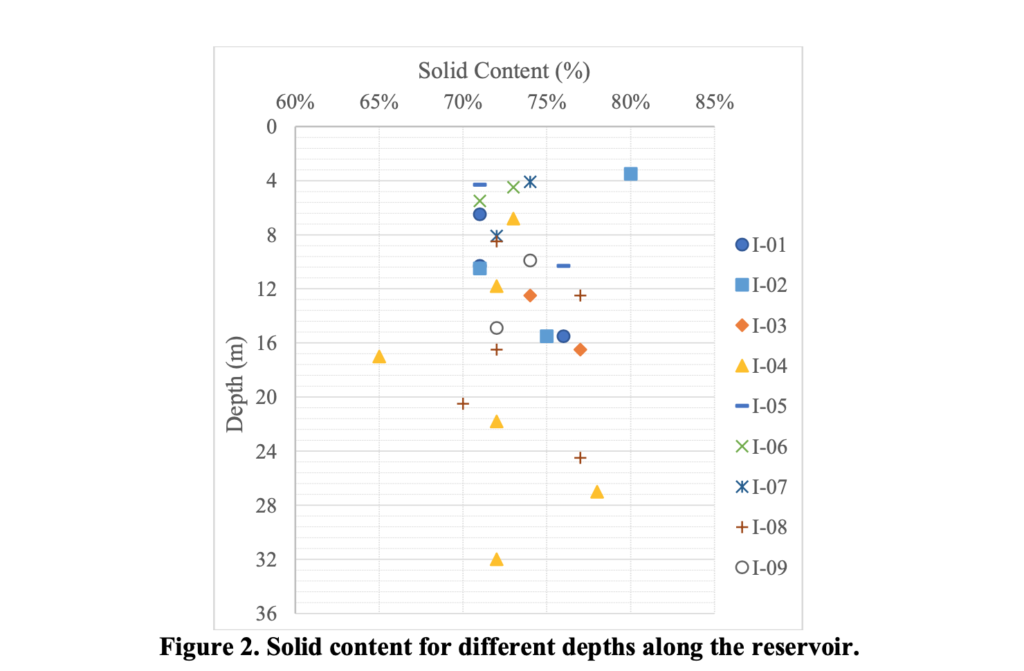

Initially, tests were carried out to determine the natural moisture content of the samples to obtain the solid content profile, spatially distributed and in-depth. Figure 2 presents the solids contents obtained in each investigation isle for different depths.

Based on the results obtained, the isles have an independent distribution of solids content along the depth, with a minimum value of 65.0 % observed on isle 04 (I-04), and a maximum of 80.0 %, on isle 02 (I-02), with an average solids content of 73.8 %.

3.1 Geotechnical Characterization

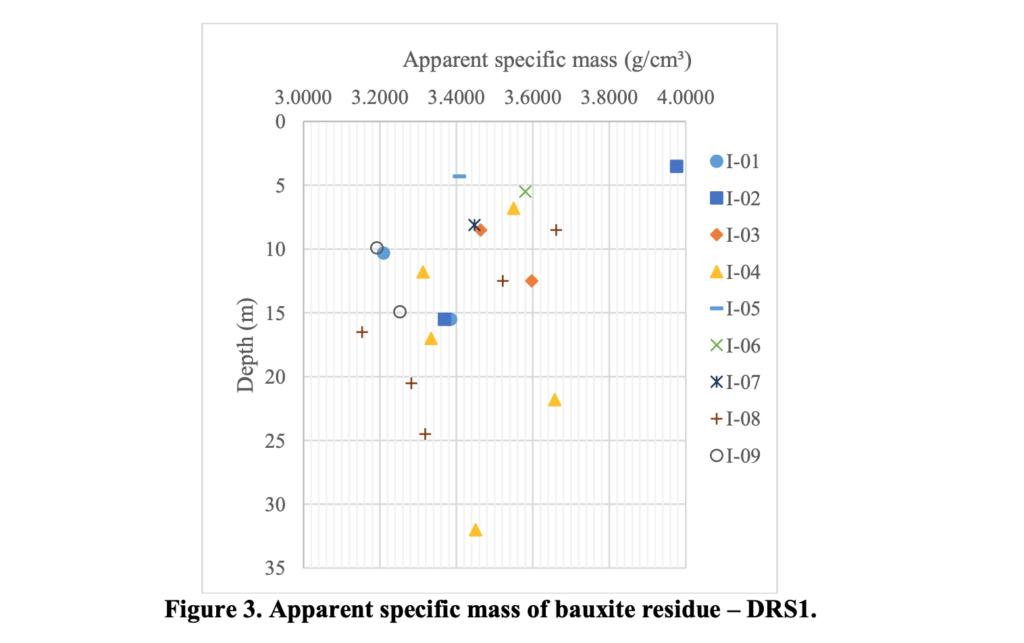

The apparent specific mass is an essential input to correlate the solid content to volumetric concentration (Cv), adopted as a reference to the model definition [9]. The apparent specific mass varied between 3.153 to 3.976 g/cm3, with an average of 3.408 g/cm3. Figure 3 presents the results by depth and isle.

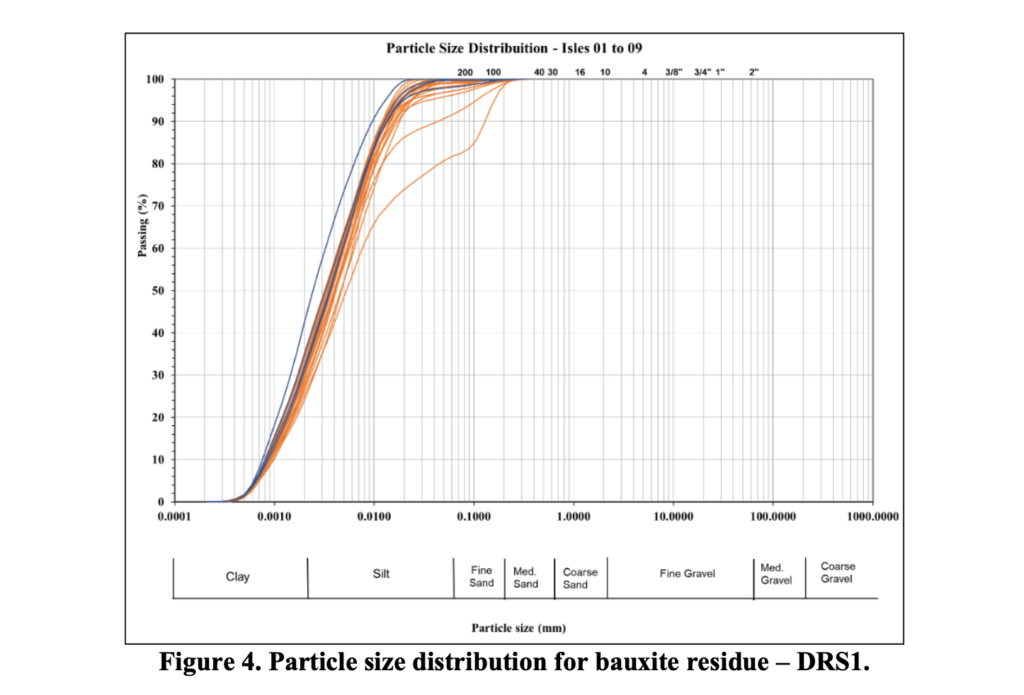

Figure 4 presents the particle size distribution of bauxite residue and shows the typical curves for a silt-clay residue. The rheological model selection considers the size distribution predominancy since models might be specifically applicable for granular or fine materials.

Based in the particle size distribution and the Atterberg limits, the bauxite residue is classified as a silt-clay of low plasticity.

3.2 Rheological Characterization

Then, tests were performed using a rotational rheometer so that two cycles of acceleration and deceleration were applied, up to a shear rate limit of 70 s-1. The samples were grouped into three categories – groups A, B, and C. Group A consisted of undisturbed samples; Group B, disturbed samples molded with their natural solid content; and Group C, disturbed samples molded with different solids contents, ranging from 30 % to 73 %.

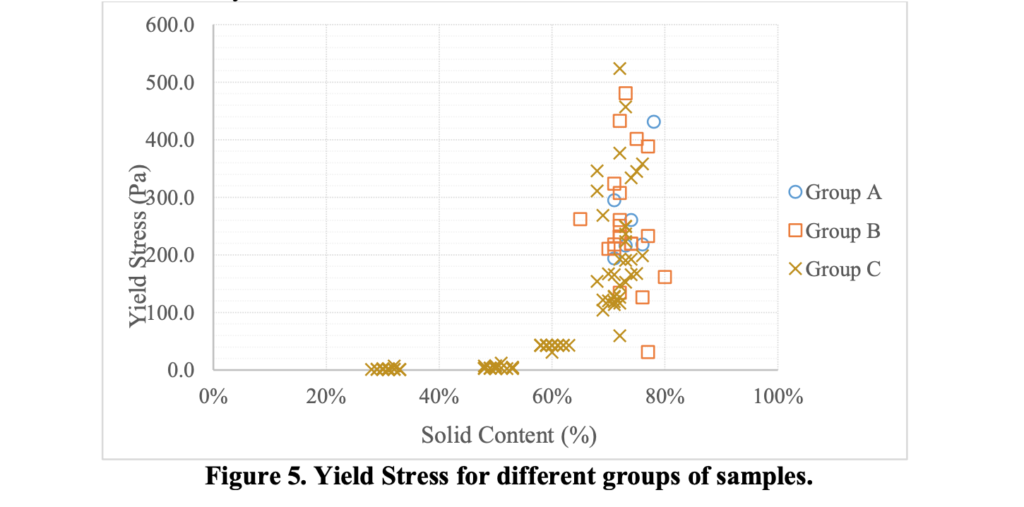

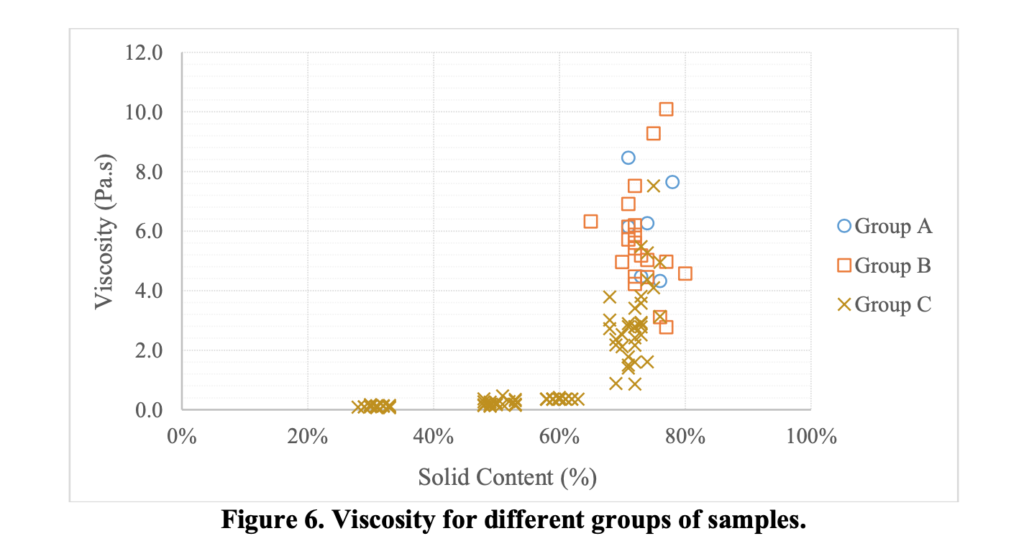

Figure 5 and Figure 6 present the results of yield stress and dynamic viscosity curves versus solids content, respectively. The rheological parameters (yield stress and viscosity) of the residue were considered reasonably representative by the mathematical model of Bingham, considering the data from the second cycle of acceleration and deceleration.

The yield stress showed similar behavior between the groups, indicating an exponential growth, proportional to the increase in solids content. In other words, the decrease in the moisture content of the material causes its strength to increase so that it begins to deform permanently. Such behavior is expected since the material appears in a less fluid state in this condition.

Additionally, the moisture content essayed for groups B and C is above 65 %, near the limit to transitional behavior observed.

Although the results mainly show a similar trend, the tests were consistent in yield stress and viscosity, approximately up to a solids content of 68 %. From that point on, it is possible to observe a pronounced dispersion of the results, with a maximum amplitude of 460 Pa between the yield strength for the same solids content of 72 %.

It is important to note that yield stress is not an intrinsic property of the material. Its value depends on the sample conditions, such as temperature, pH, and concentration, amongst others. Test conditions, instrumentation used, and, depending on the type of test, the mathematical model considered for the adjustment of results interpretation can also be cited as dependencies.

Viscosity is the property that determines the resistance of the material to the relative movement between elementary particles in relation to each other. In other words, the parameter measures the material’s internal resistance to deformation or flow.

As a result, samples with a higher solids content had an exponentially higher viscosity, indicating a greater resistance of these denser samples to flow.

Attention shall be given to the dispersion of the residue parameters in a denser condition. This may indicate that the material is in a transition range of behavior, in which the purely viscous deformations no longer govern the phenomenon. The best way to describe soils and geomaterials, in general, is by treating them as compressible, non-linear materials with viscoelastic-plastic behavior [10]. In this sense, the characterization of the transitional moment and the physical behavior of bauxite residue with about 68 % solids content should be better evaluated through oscillatory tests, which provide structural information on the material, characterizing it in terms of its viscoelastic nature.

Finally, another relevant point to investigate is the manifestation of time-dependent phenomena for bauxite residues. A more complex non-Newtonian behavior associated with time-dependent phenomena is often observed in soils and mining tailings. Phenomena such as creep, thixotropy, or rheopectic occur from the realignment of material particles on a time scale. Investigating such phenomena through specific rheological tests and understanding the residue rheological parameters in rotational and oscillatory tests provide a broad and assertive understanding of the stress-strain-time behavior of a material.

4. Conclusions

Aiming to characterize the behavior of bauxite residue when exposed to excessive deformations by such a magnitude flow and structural changes manifest themselves, this study proposed the development of rotational rheological tests with a controlled shear rate for different conditions of moisture content.

The tests, carried out with samples collected in nine isles spread over a bauxite residue deposit filtered by a drum filter, were performed using a rotational vane rheometer in two cycles of loading and unloading up to a specified shear rate. Three distinct groups of samples were considered, amongst undisturbed and disturbed samples, molded under different solid contents. The main rheological parameters, yield stress, and viscosity were estimated using Bingham’s mathematical model, applicable to fluids classified as plastic and pseudoplastic, as is the case of bauxite residue.

The yield stress and the viscosity analyzed presented an exponential growth, proportional to the increase in solids content. In other words, the decrease in the residue moisture content implied an increase in resistance for static and dynamic yield stresses. Furthermore, a dispersion of the residue parameters was evident in the solids content range above 68 %. This behavior may indicate that the material is in a transitional range, in which the purely viscous deformations no longer govern the phenomenon.

For future studies, rheological characterization of the bauxite residue should be complemented by oscillatory tests, providing characterization in terms of its viscoelastic nature. Such tests should evaluate in a more adherent way the moment of physical transition for this solid content range. Furthermore, characterization tests of time-dependent phenomena, such as creep, thixotropy, or rheopexy, may provide a more comprehensive and assertive understanding of the stress-strain- time behavior of the material.

5. References

- S. W. Jeong (2019). Shear Rate-Dependent Rheological Properties of Mine Tailings: Determination of Dynamic and Static Yield Stresses. Korea Institute of Geoscience and Mineral Resources, Daejeon.

- T. G. Mezger (2014). The rheology handbook: for users of rotational and oscillatory rheometer (4a Edição ed.). Hanover, Germany: Vincentz Network.

- Pimenta de Ávila Consultoria. Campanha de Investigação e Ensaios de Laboratório para Caracterização Reológica do Resíduo Depositado no DRS1. Technical Report. Nova Lima, 2020.

- NBR 6457:2016. Soil samples – Preparation for compaction and characterization tests. Associação Brasileira de Normas Técnicas, Rio de Janeiro, 2016.

- ABNT NBR 6459:2016. Soil – Liquid limit determination. Associação Brasileira de Normas Técnicas, Rio de Janeiro, 2016.

- ABNT NBR 7180:2016. Soil – Plasticity limit determination. Associação Brasileira de Normas Técnicas, Rio de Janeiro, 2016.

- D. G. Araújo and C. R. Nascimento. Propriedades Reológicas da Polpa de Bauxita – II. Avaliação do rotor tipo Vane. XV Jornada de Iniciação Científica – Centro de Tecnologia Mineral CETEM. 2007.

- D. Boger et al (2015). Rheological Concepts. Em R. a. Jewell. Australia: Australian Centre for Geomechanics.

- O’BRIEN, J. S., JULIEN, P.Y. Physical Properties and Mechanics of Hyperconcentrated Sediment Flows, Specialty Conference – Delineation of Landslide, Flash Flood and Debris Flow Hazards, Utah State University, 1984, 260-279.

- S. S. Vyalov (1986), Rheological Fundamentals of Soil Mechanics, Amsterdam: Elsevier Science Pub. Co.