André Faria1*, Fernando Gonçalves2 and Matheus Dutra3

Pimenta de Ávila Consultoria, Brazil

ABSTRACT

The closure is an important step applicable to the mining and/or industrial activities in a given location, in order to adequate the physical, chemical and biological conditions of the impacted area by the tailings disposal, providing a sustainable use and integrating the structure through a landscape balance. Recent tailings dam failures in Brazil, such as B-I Dam in Brumadinho (2019) and Fundão in Mariana (2015), highlighted the necessity of improvements in tailings management, with a focus on the closure and post-closure aspects. According to Requirement 10.7 (Principle 10) of the GISTM, the amount of estimated costs for planned closure, early closure, reclamation and post- closure of the tailings facility and its appurtenant structures shall be reviewed periodically to confirm that the adequate financial capacity is available for such purposes. In this aspect, given the considerable financial expenditure and the need to minimize costs for the execution of closure activities, as well as the complexity in obtaining/destining materials for the execution of closing surfaces in tailings dams, this paper aims to present the evaluation of a bauxite tailings performance as a non-structural embankment material for mining dam closure. For this, it will be presented a case study regarding the characterization of the bauxite tailings before the closure earthworks, the compaction degrees and moisture deviation obtained during the closure, as well as the performance evaluation of the bauxite tailings regarding the occurrence of cracking and fines carrying during the closure monitoring period. Complementary, the analysis of the compaction degree as a function of layer thickness and the number of passes of the compaction equipment will be presented in an experimental embankment.

INTRODUCTION

The importance of the closure and post-closure conditions is captured in the Global Industry Standard on Tailings Management (GISTM) (GTR, 2020), released in August 2020. A key point to note in the Standard is that the flood and seismic design criteria for the post-closure phase are the “Maximum Probable Precipitation” (PMP) (or “Probable Maximum Flood”, PMF) and the “Maximum Credible Earthquake” (MCE), regardless the consequence classification of the TSF. These post-closure design criteria are in line with the ANCOLD (2012) Guidelines on Tailings Dams.

One of the key closure design aspects is the cover system, which must meet multiple criteria, consider options of different levels of complexity, construction challenges, potential performance variations and cost. As described in Morrison (2022), one of the types/components of a mine cover system is the capping or sealing layer. This is usually composed of compacted clayey soil, whose thickness depends on the materials used, the site precipitation and the chemical composition of the underlying tailings. According to INAP (2017), the compacted clayey layer thickness used in mine cover systems over inert tailings generally ranges between 30 and 50 cm, typically constructed in two layers of 15 cm to 25 cm. Specific layer thickness is dependent on soil characteristics, compaction equipment employed, and the strength of underlying materials. To guarantee the desired characteristics, especially density and water content, field compaction trials are recommended, in addition to the opportunity to evaluate and calibrate quality control testing equipment (INAP, 2017).

As part of the TSF closure plan, the post-construction monitoring program is critical for evaluating whether the closure system meets performance expectations. According to Morrison (2022), a closure monitoring program should include the following areas: geotechnical stability, groundwater and seepage, surface water (quality and quantity), erosion, vegetation performance, wildlife, air quality, access and land use, as well as maintenance activities and costs. In this context, this study aims to advance the understanding of the behavior of a benign bauxite tailings when used in closure design.

METHODOLOGY

The origin of the material and its characterization is presented initially. After that, the performance of the tailings as a material for TSF closure was determined by the results obtained by: i) closure embankment, according to the compaction degrees and moisture deviation obtained during the closure; ii) monitoring period, in which the results of the closure surface monitoring are presented in terms of the visual performance of cracks and superficial sediment transport and iii) experimental embankment, through the analysis of the compaction degree as a function of layer thickness and the number of passes of the compaction equipment.

RESULTS AND DISCUSSION

This section will present the results of the geotechnical characterization of the tailings studied herein and the performance of the tailings as a material for TSF closure.

Material Characterization

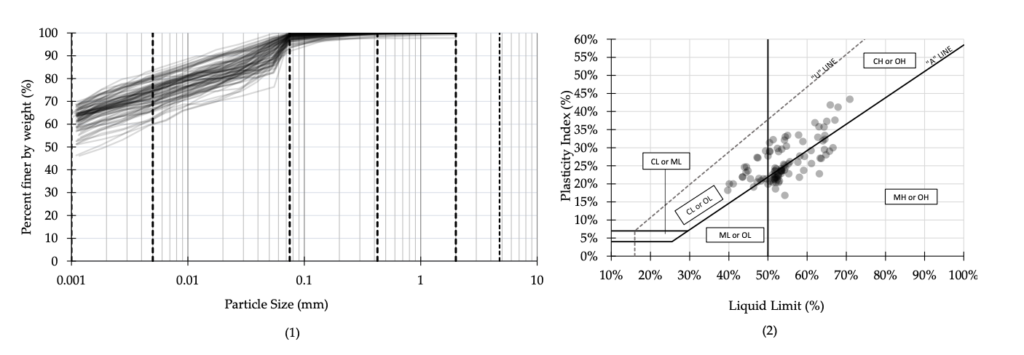

The tailings evaluated in this study is the by-product of washing ore at a bauxite mine in the state of Pará/Brazil. The tailings are geochemically benign and no chemicals are used in the ore processing. As indicated in Figure 1-1, the tailings composition (ASTM D422) is typically 2% of sand, 25% silt- sized and 73% of clay, with a specific gravity of 2.9. The Atterberg Limits were evaluated according to ABNT NBR 6459 and ABNT NBR 7180, with the results indicating medium to high plasticity (Figure 1-2). The average Liquid Limit was 54%, the Plastic Limit was 28% and Plasticity Index was 26%.

Figure 1 (1) grain size distribution curves (ASTM D422) and (2) Plasticity Index Chart

Closure Embankment

As a non-structural embankment material for TSF closure, the tailings were used in closure earthworks to construct a cover layer. The construction was conducted by conventional earthmoving equipment that was able to traffic the desiccated tailings surface. The trial earthworks totaled around 40,000 m3. It is noteworthy mentioning that for this specific case study, the tailings were used as a non-structural fill because of the project characteristics. However, the material could be used as structural fill if it is geotechnical strength properties were defined.

Lu et al. (2013) analyzed the swelling, shrinkage and cracking proprieties of compacted clay and observed that where clays are subject to seasonal moisture variation, the average axial shrinkage tends to increase with an increased moisture content of the sample, considering the same compaction degree. On this basis, to minimize the shrinkage of the compacted tailings after the construction and avoid the occurrence of cracking, the design targeted a moisture content wholly within the dry region of the compaction curve.

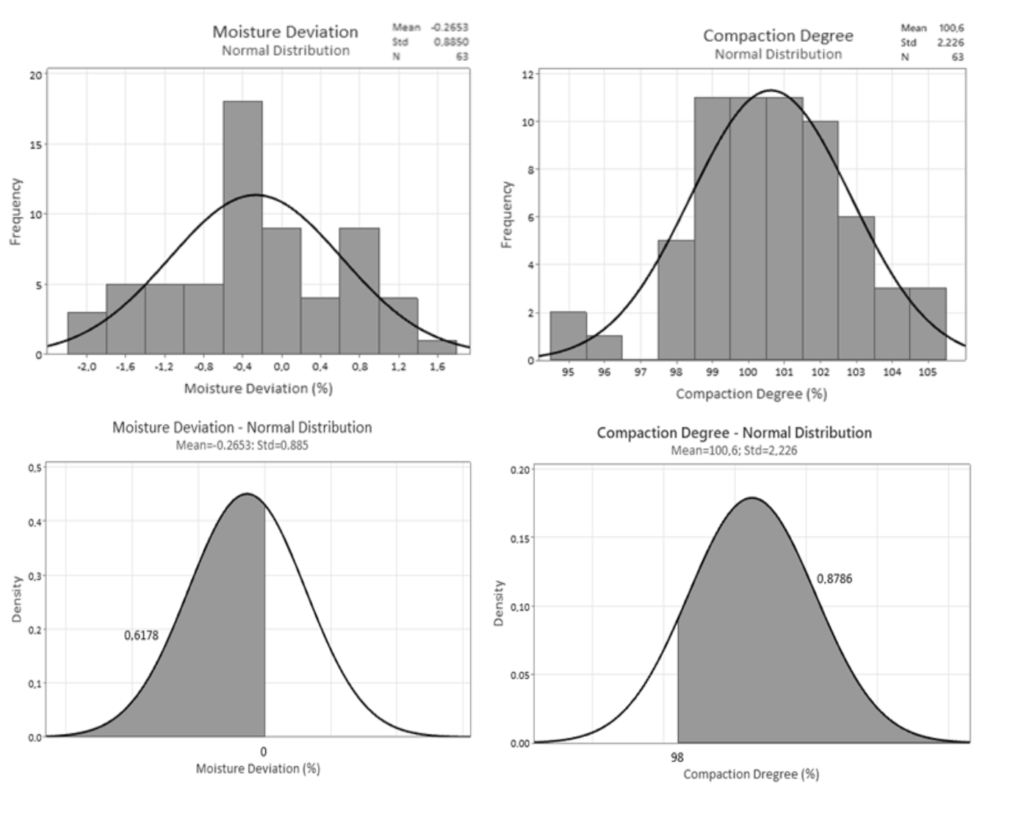

The analysis of the results indicates that the moisture deviation, on average, was -0.26%, for a standard deviation (std) of 0.88% (Figure 2). According to the normal distribution obtained for the data, the percentile equivalent to values on the dry side of Optimum Moisture Content (OMC) was approximately 61%. The moisture deviation greater than zero was primarily due to construction

being undertaken during the rainy period, an inevitable feature of working in the Amazon Basin, and the difficulty of drying back material for values above +1% of OMC.

For the compaction degree, the design target minimum value was 98% of Maximum Dry Density (MDD, Standard Proctor) to minimize both cracking and erosion of fines. For 6 passes of the compaction equipment and layer thickness of 20 cm, the average compaction achieved was 100.6% MDD. As a result of the challenges controlling the moisture deviation, some tests did not reach the required compaction and moisture value. According to de data, the percentile equivalent to values greater than 98% (specified minimum value) was approximately 87%, as shown in Figure 2.

Figure 2 Results obtained for moisture deviation and compaction degree

Monitoring Period

For this case study, the use of bauxite tailings as borrowed material for earthworks was confined to non-structural embankments and applied as a cover layer for the TSF closure. The main aspects analyzed were the visual performance of potential cracks and superficial sediment transport. From an engineering viewpoint, there is no technical reason why tailings could not be utilized for structural embankment, as long as the geotechnical strength properties are quantified.

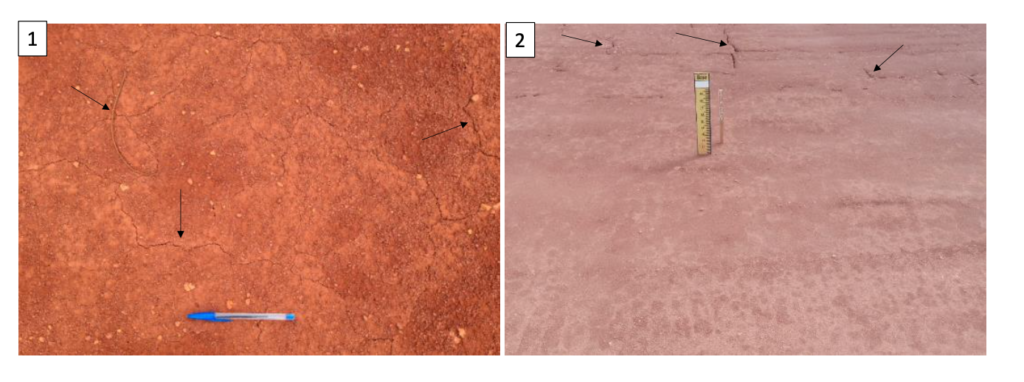

The bauxite tailings were compacted in two different conditions to compare the behavior: i) according to the closure embankment previously presented; and ii) without controlled compaction degree and moisture content deviation, using only tracked vehicles to compact. Both embankments were constructed at the same tailings disposal plant, using the same materials and exposed to the same climatic and environmental conditions.

Figure 3 shows some differences (indicated with arrows) between the magnitude of the cracks of the well-compacted and track-compacted embankments, highlighting that the cracks for the uncontrolled embankment (Figure 3-2) were relatively larger than the cracks for the controlled embankment (Figure 3-1).

Figure 3 Difference of cracks size between controlled (3-1) and uncontrolled embankment (3-2)

Another observable aspect, best viewed in photos in Figure 4, is the erosion of fine-grained tailings

after rainy events and redeposition close to the dam spillway (lowest region of the surface).

Compaction in the spillway region was carried out as per the embankment in picture 4-1. Despite that, pictures 4-2 and 4-3 show clearly that the redeposited fine material in the spillway region underwent extensive shrinkage cracking, that potentially extended into the underlying compacted tailings and subsequent drying.

Picture 4-2 was taken after rainy events and picture 4-3 after a dry period. The desiccated surface is similar to the usual wet slurry deposited bauxite tailings following drying. From the field trial, once the TSF is capped and before vegetation establishes, surface erosion of the compacted cap is sufficient to cause silting up around the spillway, potentially extending to waterways downstream the dam from spillway discharge, irrespective of the compaction effort applied to the tailings cap. Additional erosion protection measures will therefore be required for the compacted tailings cover in the early stage of TSF closure.

Figure 4 Compaction around the spillway (4-1), silting during the rainy season (4-2) and dry season (4-3)

Experimental Embankment

Based on the results and evaluation of the closure embankment previously presented, the average compaction degree obtained was higher than the design minimum of 98% MDD. Following on from this initial trial and to ensure greater construction flexibility for closure of other TSFs onsite, an experimental embankment was constructed to evaluate increasing the layer thickness above the 20 cm layer proposed for the cover. In this study, the layer thickness refers to the condition before compaction i.e., loose condition.

In addition to assessing the compaction degree as a function of the layer thickness, the evolution of the compaction degree as a function of the number of passes of the compactor was also investigated. The experimental program included the execution of loose layer thicknesses of 25, 30, 35, 40, 50 and 60 cm.

Two tests were carried out to determine the compaction degree for each specified layer thickness and number of passes. Two layers were constructed for each thickness of 25, 30 and 35 cm, and one layer was constructed for each thickness of 40, 50 and 60 cm. The test specified for determining the compaction degree was the Hilf rapid compaction method (ABNT NBR 12.102) and the field density was determined from the collection of undisturbed samples using a drive-in sampler. Samples were collected at the base of the compacted layer and, for layers of 50 cm and 60 cm thickness, samples were additionally collected at the top of the layer, to compare the compaction degree with the base of the layer. The compaction equipment used was a self-propelled padfoot roller (CAT-CP54B).

As the trial aimed to evaluate the compaction degree as a function of layer thickness and the number of passes of the compactor, a minimum degree of compaction to be achieved was not defined. However, the intention was to reach, with the number of passes of the compactor roller, the minimum compaction degree required for the TSF closure design, which was 98% MDD (Standard Proctor). For the moisture deviation, the values should be within the limit of -2% and +1% of Optimum Moisture Content (OMC).

The steps for carrying out the experimental embankment consisted of i) releasing the tailings, ii) spreading the material with a bulldozer, iii) treating the material (homogenization and moisture control), iv) leveling it with a motor grader and v) compacting it with a compactor roller. Caution was taken for the passage of equipment so that in the center of the layer there was only passage of the drum of the compactor roller. The samples for the execution of the Hilf tests, both undisturbed and deformed, were collected in the central portion of the layer, where there was no passage of the equipment tires.

The results of the compaction degree as a function of layer thickness and number of passes of the compactor are shown in Figure 5, as well as those related to the base and top of the 50 cm and 60 cm thickness layer. A trendline was plotted in the results for each layer thickness for better visualization of the data trend, and the best fit (greater R2) was achieved by a logarithmic function. In the graph, reference lines were drawn for the compaction degree of 95% and 98%.

Figure 5 Compaction degree (C.D.): (1) as a function of layer thickness and the number of passes of the compactor; and (2) of the base and top of the 50 cm and 60 cm thickness layers

According to Figure 5-1, as expected, all analyzed layer thickness showed a tendency towards an increase in the compaction degree (C.D.), with an increase in the number of passes of the compactor roller. The layers showed a reduction in C.D. with an increase in layer thickness, except for the 60 cm layer that presented C.D. greater than the 50 cm layer. This anomalous behavior can be explained because, at the base of the 50 cm and 60 cm layers, the compaction energy coming from the compactor roller is very low, which makes the results more scattered.

For the 25 cm thickness layer, the average C.D. is greater than 98% from 6 passes of the compactor roller and the average C.D. is greater than 95% for all values of passes analyzed. The results for the 30 cm and 35 cm thickness layer were close, with the average values of C.D. for the 30 cm thickness slightly above the values for 35 cm. Additionally, for 30 cm and 35 cm thickness, the average C.D. was greater than 98% for 12 passes of the compactor roller and the average C.D. was greater than 95% for 8 passes of the compactor. Finally, still considering Figure 5-1, for the 40, 50 and 60 cm thickness, the average C.D. was less than 95% for all pass values used, indicating that the compaction energy of the compactor roller did not efficiently reach the base of the layers for the pass values used. For reference, the Caterpillar Performance Handbook lists a maximum layer thickness of 20 cm for an 18-tonne pad foot compactor.

Analyzing Figure 5-2, there was a significant difference in the C.D. for the top and bottom regions of the 50 cm and 60 cm thickness layers, wherein for the top region, the average C.D. is greater than 95% for all analyzed values of equipment passes. This indicates that the compaction energy is efficient for compaction in the upper region, but not efficient for compaction in the lower region of the layer. Specifying the test depth interval for verifying the level of compaction is therefore fundamental to any earthwork’s specification, to avoid accepting a densified crust, with potentially looser material at depth.

Findings Summary

To summarize the main findings of the study, it was possible to verify that:

Closure Embankment: based on the results, using loose layers of 20 cm thickness, the average compaction degree of the compacted embankment exceeded the minimum required after 6 passes of a pad foot roller.

Monitoring Period: the test area compacted under a moisture content below the Optimum Moisture Content (dry region of the compaction curve) and at higher compaction degrees, showed less cracking when compared to the test area performed without compaction control. Surface erosion of the completed earthworks was considerable due to rain runoff, even for the controlled compaction closure works.

Experimental Embankment: for a 25 cm loose layer thickness, the compaction degree of 95% was achieved with 4 passes of the compactor and 98% with 6 passes. For a 30 cm layer thickness, the compaction degree of 95% was achieved with 7 passes of the compactor and for 98%, with 11 passes. Furthermore, with layers thicker than 35 cm loose-placed, greater variation in the C.D. for the base of the layer is to be expected. Finally, it was confirmed that the compaction energy is more efficient in the upper region, showing the importance to verify the correct layer thickness during the design phase.

CONCLUSION

This paper presented a case study focusing on the evaluation of bauxite tailings performance as a material for mining dam closure.

For the field scale closure earthworks, the medium to high plasticity silt/clay tailings showed reasonable workability, with the earthworks contractor able to adjust the moisture content in situ, where on the dry side of OMC. In the Amazon Basin climate, drying back tailings on the wet side of OMC was more challenging. Once the tailings were conditioned within the required moisture content limits, achieving the specified degrees of compaction was no different than the local tropical residual soils. Only conventional compaction equipment and methods were required.

The use of bauxite dry tailings as borrowed material for a compacted embankment is practicable if its limitations are known. The results indicated that once exposed to drying, the medium to high plasticity leads to superficial cracking from shrinkage. Although the bauxite tailings are non- hazardous/inert, it is prone to erosion and requires additional controls to be in place until vegetation establishes. This is particularly relevant where surface drainage leads to an environmental receptor.

Finally, the sustainable aspect associated with the reuse of tailings in closure design should be recognized. Substituting a substantial volume of tailings into the closure landform offers a substantial cost reduction over obtaining naturally occurring soils as borrowed material.

ACKNOWLEDGEMENTS

The authors thank Pimenta de Ávila Consultoria for providing the data and encouraging the academic production of practical applications.

REFERENCES

ABNT NBR 10004. (2004) ‘Solid waste – Classification’.

ABNT NBR 6459. (2016) ‘Soil – Liquid limit determination’.

ABNT NBR 7180. (2016) ‘Soil – Plastic limit determination’.

ABNT NBR 12102. (2020) ‘Soil – Compaction control by Hilf method’.

Australian National Committee on Large Dams (ANCOLD). (2012) ‘Guidelines on Tailings Dams – Planning, Design, Construction, Operation and Closure’.

ASTM D422-63(2007). (2014) ‘Standard Test Method for Particle-Size Analysis of Soils (Withdrawn 2016)’.

Global Tailings Review (GTR). (2020) ‘Global Industry Standard on Tailings Management’.

International Network for Acid Prevention (INAP). (2017) ‘Global Cover Systems Design – Technical Guidance Document’, Melbourne, Australia.

Lu, H., He, W., Liao, Z., and Chen, W. (2013) ‘The Swelling, Shrinkage, and Cracking Properties of Compacted Clay’, Electronic Journal of Geotechnical Engineering, 18, pp. 1037–1044.

Morrison, K. F. (2022) Tailings Management Handbook – A Life-Cycle Approach, Society for Mining, Metallurgy & Exploration, Canada.